Great in Supply Chain Management

It is only natural that many companies today want to go from good to great in Supply Chain Excellence.

It takes a lot of effort to go from good to great in any field of endeavour. It takes even more discipline and technique, than the effort.

But, there is another missing ingredient which does not occur to most people, right until it is too late. I will come to this important point soon.

Recently, while watching the film “The Legend Of Bagger Vance” with my sons, I was struck with how important the caddies are for the competitors.

As anyone who has watched a golf match knows, every shot counts.

Smallest putts count as a full stroke, and can easily turn a potential multi-million dollar prize winner into a near miss

Here, without going too much into the respective careers of these billion-dollar golfers (all the reasons for their change of fortunes),

I would like to state one simple fact – that caddies play a significant role in golfers’ fortunes, probably much more than most people, including golfers themselves realize.

If you have been following the fortunes of the world’s top golfers, you might have noticed the difference that a change of caddy made to the careers of Adam Scott and Tiger Woods.

In case you have not seen the movie yet, below is a five minute YouTube clip to give you an idea:

Idea of Great in Supply Chain

Great caddies will go to great lengths to collect all the relevant information on distances, slopes and other relevant facts to enable the golfer to make the right decisions and execute them with confidence.

So, what is the difference between a great caddie, and a merely good caddie?

They all walk the course and measure distances from all plausible spots to the pin.

They all know the slope of the greens by heart, but the great caddies will sometimes roll hundreds of balls just to understand how the ball actually rolls on the green.

That tactile feeling allows them to read the putts much better than other caddies.

Sure, it is hard work; and, in these days of modern technology, perhaps a bit redundant.

However, their devotion to their craft makes them want to leave no stone unturned in collecting as much relevant information as possible to assist the golfer.

Another YouTube clip from the same movie might make it more real for those who want to invest 3.5 minutes to see this:

Invest of Great in Supply Chain

Now, you may wonder why am I talking about caddies and golfer?

Because late last year, one of our consultants asked me why we wanted to manually plot over 1,400 locations and over 250,000 monthly movements on a map.

His point was very valid. Supply chain software, Excel and other computer aids make it unnecessary to do so.

In our company itself, we have already amassed supply chain models created over the last 15 years of our existence that can grab a dataset like this and spit out answers in minutes.

It is far too easy to pump out Excel charts by the dozen without fully comprehending the significance of the story that the data is trying to tell.

To fully understand this story, one must spend time listening to the data.

For this reason, on nearly every project, we take care to manually plot the data at least till the entire project team has a very good appreciation of the operations being analyzed.

Yes, it makes us work well into the night in many case.

And, yes it is arduous work Great in Supply Chain

But, this dedication to our craft begins with getting a tactile feel for the operation in its entirety – which is best achieved through such an exercise.

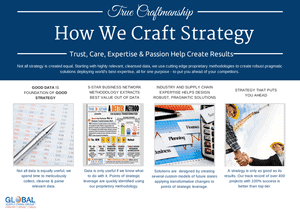

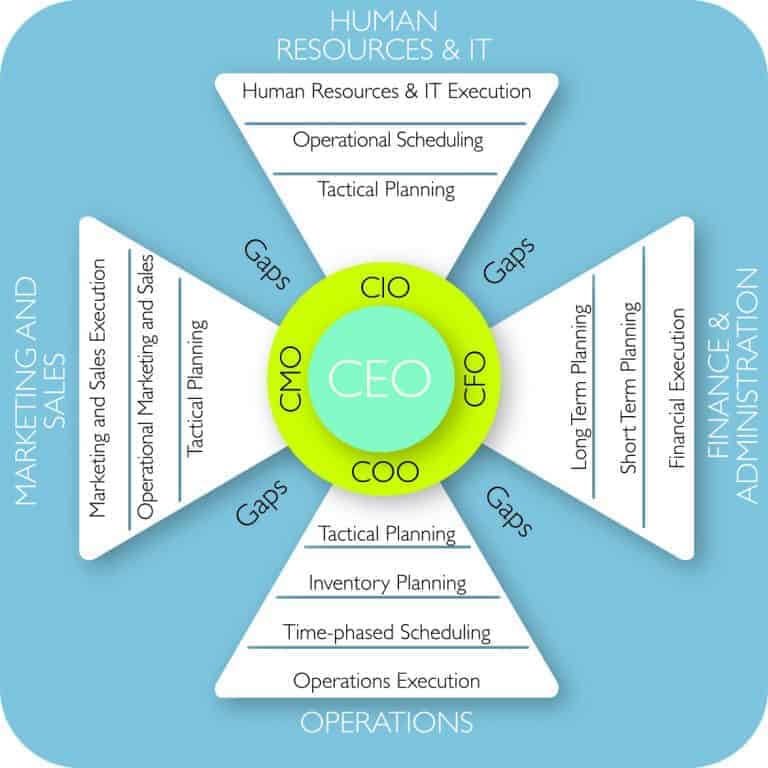

We want to make sure we have studied each and every avenue of change, tested every lever of transformation, and carefully selected only the most impactful few, so that we can assist the CEOs and executives who rely on us to guide them towards success.

After all, this attention to detail makes all the difference between a good strategy and a bad one.

Difference between a successful business transformation saving our clients millions (or sometimes hundreds of millions) of dollars, and unsuccessful ones (that one reads about in the press) that do more damage than good.

Luckily, for the last 14 and half years, so far each one of our project has been a success, and we plan to keep that track record.

Strategy of Great in Supply Chain